|

ANIMAL SLIDES:

<Researchers><Test Data> <Equipment> |

|

|

|

DEVELOPMENT |

|

p3 |

|

<Previous>

<Full

size>

<Next>

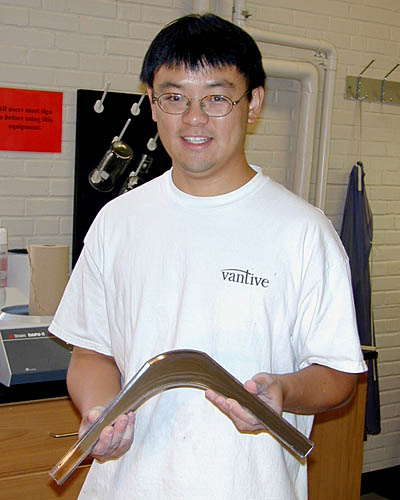

An Auburn University Ph.D. student in material science engineering assisted in polishing the interior of the flight tube (one half shown)

|

|

|

|

1

<Previous>

<Full

size>

<Next>

Early stages of development in ANIMAL

|

|

2 |

|

<Previous>

<Full

size>

<Next>

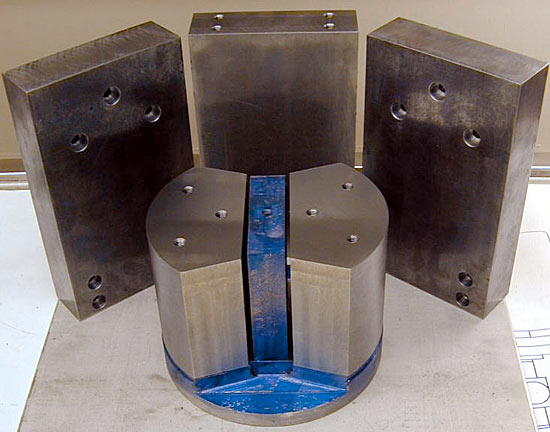

A round of cold-rolled mild steel was used for

machining the pole pieces of the electromagnet.

|

|

3 |

|

<Previous>

<Full

size>

<Next>

Auburn university machinist fabricating the pole

pieces of the electromagnet

|

|

4 |

|

<Previous>

<Full

size>

<Next>

Frame (three pieces) and pole pieces of the

electromagnet following machining

|

|

5 |

<Previous>

<Full

size>

<Next>

This is a test text: Auburn Noble Isotope Mass Analysis Laboratory

Department of Geology and Geography

Auburn Noble Isotope Mass Analysis Laboratory Department of Geology

and Geography

|

|

6 |

|

<Previous>

<Full

size>

<Next>

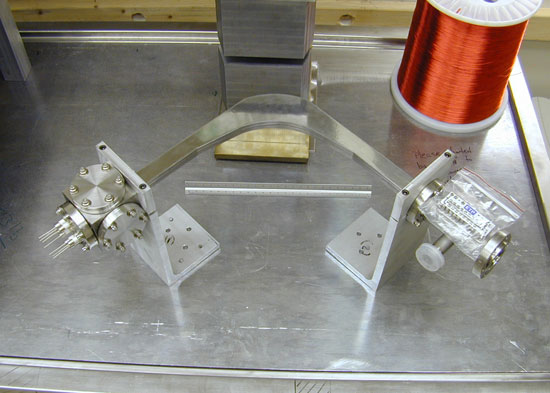

Early development and testing of the placement

for the source, flight tube, detector (note ETP multiplier) and

electromagnet. The fine wire, at right, was used in winding the

secondary electromagnet coils (for fine adjustment and computer

control).

|

|

7 |

|

<Previous>

<Full

size>

<Next>

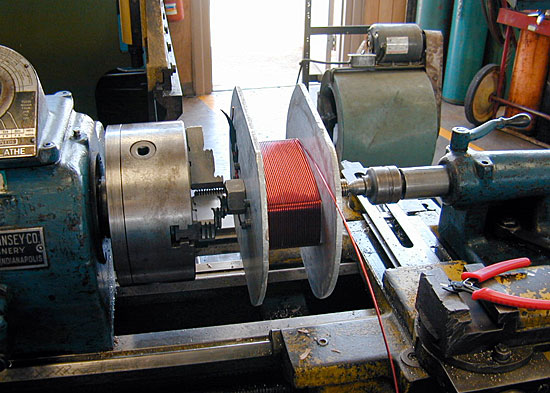

Winding a main coil for coarse control of the

electromagnet

|

|

8 |

|

<Previous>

<Full

size>

<Next>

AU Geology graduate student Sarah Lavallee

winding a coil for the main (coarse) magnet control, in the Auburn

University Central Machine Shop

|

|

p1 |

|

<Previous>

<Full

size>

<Next>

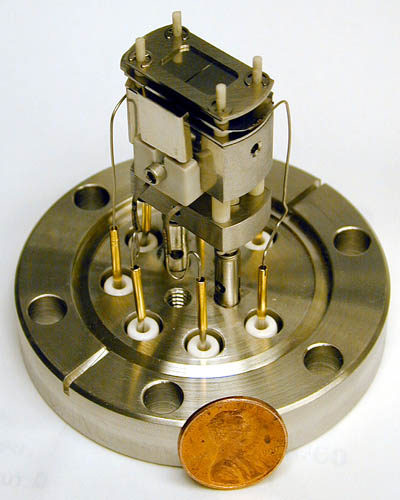

View of the electron-impact ion source, based on

Wallington (1971; after Nier, 1947). The source was designed to fit

conveniently within a 2.75" cube, and is mounted on a 2.75"

feedthrough flange

|

|

p2 |

|

<Previous>

<Full

size>

<Next>

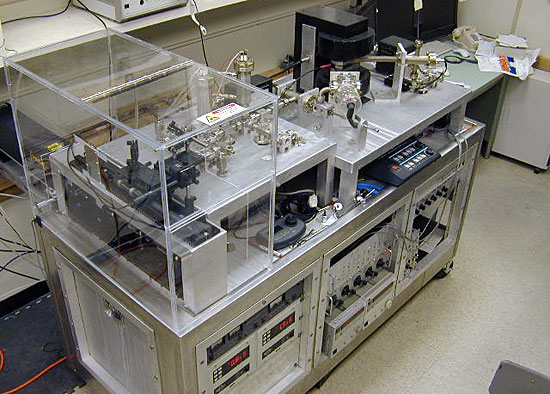

The table design and equipment layout permits the

extraction line and mass spectrometer to be baked independently at

temperatures up to 350 °C.

|

|

9 |

<Previous>

<Full

size>

<Next>

The complete system.

|

|

Top of Page |